Services

Custom woodworking without compromise. We stand by our work and customer satisfaction is always our goal.

INSTALLATION PHILOSOPHY

At Prewitt Hardwood Floors Inc, we pride ourselves on being conscientious woodworkers. We offer dust-free installations for our site-finished and pre-finished flooring, with the use of cutting tents as well as hooking vacuums to all of our milling equipment. We glue and nail any flooring that is over 4” in width. The moisture content on the subfloor and wood is carefully monitored. We are experts at exceeding the industry standards on all of our installations.

A great installation must first start with a flat, clean, and dry subfloor without squeaks and movement. We offer complete subfloor sanding and liquid moisture barrier installation, allowing us to glue your flooring down as needed. Whether your floors are pre-finished or site-finished, sanding the seams of your subfloor with an edger will not simply flatten your floor to an acceptable level. Drum sanding your sub floor will work out the ridges over a greater area of your floor and create a much flatter surface. This also removes the sheetrock and paint residues that keep your floor from completely drying out. Once sanded, we can dry out your floor to the same moisture content as the wood being installed in order to prevent future movement.

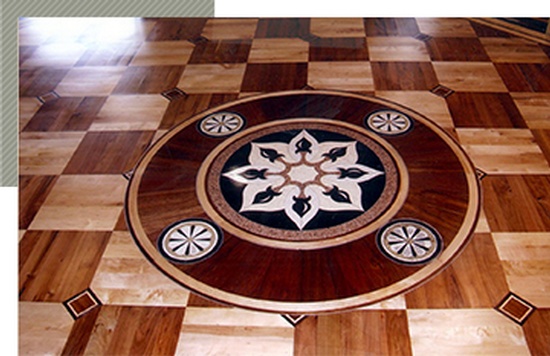

CUSTOM INSTALLATIONS

Rich and his sons are creative artisans and really enjoy custom installation challenges. Feel free to browse our gallery section to see some of our custom work. Custom patterns, species, colors, borders and inlays have become a signature for us. If you want to create a unique floor that stands apart from all others, we can help you design, custom mill, and install it without a hitch.

CUSTOM MILLWORK

We currently have a 4,000 sq. ft. milling facility where we hand make all of our floor registers, transitions, stair treads and components, and medallions as well as our custom flooring. We have a beautiful spray booth where we can pre-finish components to match any color and sheen level of any project including hand distressing and 10 coats of finish.

SANDING & FINISHING PHILOSOPHY

At Prewitt Hardwood Floors, Inc., our goal is to provide the cleanest, flattest and best protected floors in the industry. Non-conscientious mechanics can over-sand your floors, thus reducing the overall life of your floors. Use of the wrong finishes or finishing procedures that allow deep wood penetration will require over-sanding at a future refinish. Our goal is to provide you with the most durable topical finishes in the industry. With proper care and maintenance, a hardwood floor can last over 100 years. We use Bona Kemi’s commercial-grade finishes and pride ourselves with giving you a floor and finish that can last a lifetime. Give us a call and we can explain the differences between oil-modified, Swedish, low VOC water-base, penetrating oils and ultraviolet cured finishes. All are available in multiple sheen levels and each hold their own advantages. We can provide hundreds of stain color options and many finish options to custom cater to your specific needs and lifestyle.

DUST CONTROL OPTIONS

As our industry has evolved, we now have the option to keep the dust and inconvenience out of your home. We have made this a priority and are on the cutting edge of this technology. Dust control comes in four different forms. When you get competitive estimates for your project, many contractors will say that they contain dust, but most have inadequate systems.

The “old school” method is to hang plastic and use cloth bag collection on their equipment, vacuuming up when done. This method has created many homeowner horror stories and a negative view of our industry.

The next advancement has been to hang plastic and attach shop vacuums to the sanding equipment. This is limited by the pull of the vacuum, the effectiveness of the skirting and the maintenance of the equipment. We have moved beyond both of these methods.

The next method, which we offer at no additional charge, is true dust containment. This utilizes a powerful vacuum and cyclone action to collect the dust. Fine filters should be utilized on the equipment. Maintenance and attentiveness to the tools and hoses are a must. Though these systems boast over 90 percent containment, I believe it is closer to a little over 80 percent since the vacuums are containing dust in the home and the reservoirs must be emptied often. Combined with a little bit of clean up and detailing, this has been a very successful system.

DUST EXTRACTION

For the customer that wants all dust captured, this is the system. We do charge additional, due to the expense of running and maintaining the equipment. We utilize a 29 h.p. curb mounted vacuum that overpowers all equipment and pulls the dust to the curb. This method has proven to be 100 percent dust-free.

We have clients visiting our Flooring Store from across Battle Ground, Ridgefield, Woodland, Yale, Cougar, Vancouver, Gresham, Portland, and the surrounding areas.